Anjing Road, Xiaolan, Zhongshan, Guangdong, China

info@mes-drive.com

08.00 AM-09.00 PM

In early October, Amazon unveiled its latest Prime Air drone prototype in Los Angeles, and UPS announced a parallel high‑altitude delivery test in Dallas. Both companies are targeting the first fully autonomous drone package deliveries to consumers within the next year. The press release, which drew millions of views across Reddit, Twitter, and mainstream news outlets, marked a turning point: if major logistics players can overcome regulatory, safety, and technical hurdles, millions of small, battery‑powered aircraft could soon be navigating city skies to deliver medicines, groceries, and parcels.

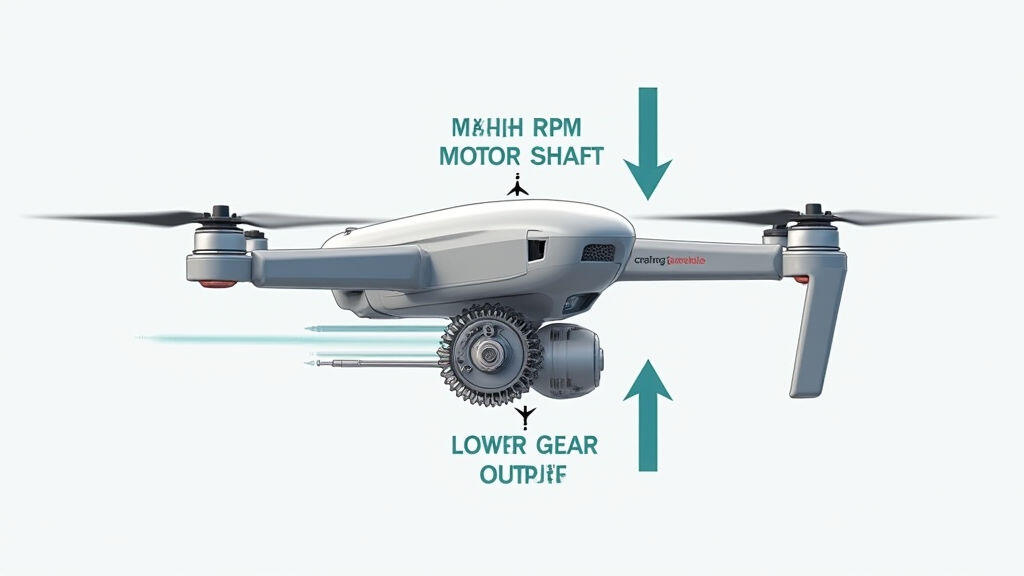

The article may focus on AI navigation, battery chemistry or regulatory frameworks, but underneath the buzz is a straightforward engineering truth: every functioning drone relies on a compact, lightweight gear motor—often called a reducer motor—to translate the raw electricity of a small motor into the quiet, controlled rotors that lift, turn, and stabilize the aircraft. As Amazon and UPS push the envelope of payload, flight time, and speed, the demand for high‑performance gear motors is poised to skyrocket.

Delivery drones must solve three intertwined problems:

Reduce the motor speed by a factor of 10 or even 20, and you turn a lab‑scale, gigawatt‑level engine into a 20‑wheel golf ball that can lift a 1 kg package. A safe, efficient gear motor is the backbone of that conversion, reducing high rpm to the ~3–5 kHz needed to spin rotors of only a few centimeters. The gear motor also contributes less than 5 % to the drone’s total weight in today’s designs, yet its failure can abort an entire delivery mission.

Both Amazon and UPS have factored in gear motor specifications early in their design work. The airlines focus on gear trains that maintain high efficiency (> 95 %) at 70 % of maximum torque, since battery life is capped by the motor’s heat dissipation. Companies also want gear ratios between 30:1 and 50:1, striking a balance between torque amplification and space economy. To meet this, manufacturers have turned to advanced metallurgy and precision gear cutting: high‑strength steel alloys and ceramic hybrids reduce wear and enable mass‑production of identical units.

Recent advancements in planetary gearsets and cycloidal drives offer even lower backlash and higher load capacity, aligning with UPS’s interest in a single motor architecture that can power all four rotors (less assembly complexity, lesser failure modes). Simultaneously, Amazon’s flagship Prime Air uses a blended gear selector—a compound gear arrangement that allows mid‑flight speed changes, providing pilots with better climb rates in different weather conditions.

According to a recent Gartner report, the global light‑utility drone market is projected to reach 1.8 million units annually by 2029, a 4.5‑fold increase from 2025. This translates into a direct need for hundreds of millions of gear motor units—for each rotor, each hover controller, and each potential spare part.

The cumulative effect is a clear supply chain ripple: smaller gear motor suppliers may be squeezed by demand, while larger OEMs amplify the need for a robust, defect‑free production line. The ripple reaches beyond drones: kit planes, industrial drones, and hobbyist creators also look for premium gearmotor solutions, driving innovation in gear geometry and materials.

One of the most pressing challenges to drone delivery is the regulatory framework. The Federal Aviation Administration’s (FAA) Part 135 schedules for unmanned aircraft require each motor system to have redundant safety features. This means gear motors need vibration‑damped bearings, self‑diagnostic sensors, and rapid shutdown capabilities. The new FAA Green Light Initiative mandates that drones meet certified safety thresholds before commercial work.

From a product perspective, gear motors are now being examined not only for their mechanical performance but also for electrical isolation, EMI shielding, and remotely‑monitorable health indicators. Companies like Singer Motors are developing gear heads with integrated temperature sensors that can report data back to cloud dashboards, allowing Amazon and UPS to pre‑emptively spot motor derating and pre‑empt possible delays.

What does the future hold for gear motors in a world of delivery drones?

While the regulatory and technical hurdles are still significant, the convergence of Amazon’s and UPS’s high‑profile tests with the industry‑wide push for lightweight gear motors portends a boom that could reshape the logistics sector.

Amazon’s ambitious drone delivery trials and UPS’s experimental programs highlight a quiet revolution in commercial logistics. As drones look to replace a fraction of last‑mile deliveries, every kilogram of payload depends on the reliable, efficient powertrain of a gear motor. The rising demand for sophisticated, lightweight gear reducers is driving innovation in materials, design, and manufacturing across the industry. If the FAA’s stringent safety standards are met and drones debut on a commercial scale, the gear motor will be an unsung hero soaring alongside Amazon’s and UPS’s drones, turning the vision of rapid, on‑demand deliveries into everyday reality.

Leave A Reply

Your email address will not be published. Required fiels are marked